VD10

Atmospheric distillation of Fuels and Solvents

Innovative Video Distillation

ASTM D86, D850, D1078

ISO 3405, ISO 918, ISO 4626

IP123, IP195, JIS K2254, and other methods

Patent(s) :

US12247936

CN202290000667

The Video Distillation VD10 revolutionizes distillation testing by bringing unmatched automation and precision to the analysis of atmospheric distillation of petroleum products.

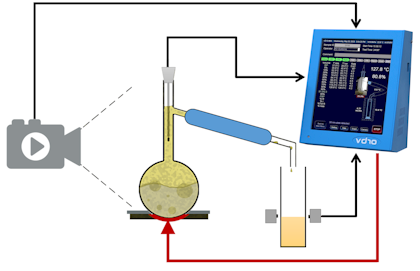

The powerful algorithm assisted by video camera (patent pending) analyzes in real time the boiling behavior of the sample in the flask during the distillation run and applies optimal heating to strictly respect conditions of the chosen method.

As an experienced manual distillation operator, visual monitoring allows the VD10 to detect boiling changes early enough ato anticipate the appropriate heating regulation to reach IBP, 5% in given time, and the distillation rate control. No need for programming or optimization, the distillation test is perfect from the first try even for unknown or difficult samples like biofuels.

Gasoline

Refineries

Special fuels

Pipeline and terminals

Military fuel testing

Jet fuel testing

ASTM D86, D850, D1078

ISO 3405, ISO 918

IP 123, IP 195

DIN 51751

JIS K2254

GOST 2177

The VD10 is the most advanced distillation instrument available today. Developed by AD Systems, the original imaging system makes the VD10 truly automatic distillation apparatus not requiring any programming, drastically reducing operator time.

High quality components, precise sensors and robust construction assure high reliability, heavy-duty use with minimum maintenance.

User friendly interface contains all necessary features for test traceability, quality assurance, diagnostics, communication and safety.

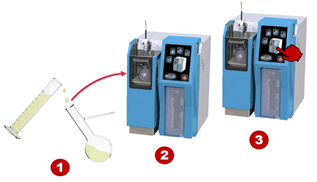

Intelligent video system assists operator by checking proper installation of flask, probe and heater plate.

The VD10 advanced control algorithm uses image analysis to perfectly control the distillation run.

No need for any programming or optimization

The entire procedure is fully automated: heating the flask, regulating the condenser and receiver temperatures, measuring vapor temperatures and volume, detecting IBP, FBP and recording all data. At the end of the test, the heater is automatically lowered and cooled down quickly. Results are displayed, saved, printed, sent to LIMS.

| Technical Specification | Description |

| Test method | ASTM D86, D850, D1078, IP 123, IP 195 DIN 51751, ISO 3405, GOST 2177, JIS K2254 |

| Vapor Temperature | Pt100 class A with 10 points embedded calibration data (Factory & User) Automatic probe ID detection. Range: 0 - 450°C, accuracy 0.1°C |

| Heater | Low mass/low voltage heater. Video camera assisted algorithm calculates optimum heating in real-time. Distillation range: 2-10 ml/min Automatic heater lift. Specially designed fan for fast cooling. |

| Condenser | Hybrid: Solid state/liquid cooled condenser. Sealed system for long life operation. Very fast temperature stabilization at setpoint in the range of 0 - 65 °C |

| Receiver |

Homogeneous temperate receiver chamber in the range 10 to 45°C for groups 1 to 4 (range 0°C to 45°C is technically possible) |

| Ambient sensors | Built-in barometric presure sensor 50 to 110 kPa, accuracy 0.1KPa Ambient temperature and humidity sensors supplied in standard |

| User interface | Full-color touch screen; multilanguage; Smart operator assistance features |

| Communication | USB, RS232, Ethernet, Wireless (Wi-Fi) |

| Fire safety | UV sensor for fire detection. Built-in fire extinguisher manifold. External alarm connection. |

| Emission reduction | VOC extraction included in standard |

| Electrical | 100-240 VAC 50/60 Hz |

| Physical | (WxDxH) 42cm x 48cm x 63cm; weight: 50 Kg |

| Accessories | Dry point kits; printer; bar code reader |

| Operation conditions | Temperature 10°C - 35 °C Humidity up to 90%, non-condensing |

Gasoline

Ethanol blended Gasoline

Diesel

Biodiesel

Jet Fuel

Naphtha

Solvents

Refinery streams

Heavy oils